How Industrial Customers Can Lower their Electricity Bills through Rate Design

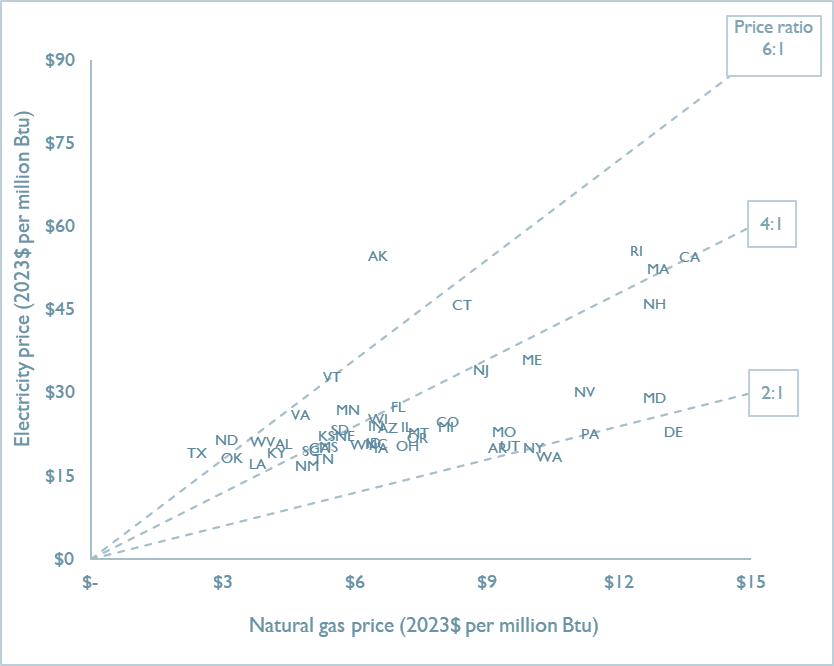

U.S. industrial competitiveness relies on affordable energy. For some industries, process heating drives the majority of energy use and energy costs. Electrifying industrial process heat can offer manufacturing facilities energy efficiency gains, operational improvements, and reduction of onsite emissions. However, a widespread switch from fossil-based to electric heating has yet to occur because of the “spark gap”, or the unfavorable ratio of electricity to fuel prices that a given facility faces (Figure 1). While in some regions, high-efficiency industrial heat pumps can close the gap, other strategies are likely necessary to make the case for electrification cost-effectiveness. For example, alternative rate design can lower electricity bills for industrial facilities that electrify.

Figure 1. Spark gap for industrial customers in the United States by state

Source: Synapse analysis of U.S. Energy Information Administration State Energy Database System 2023.

Alternative rate structures for more affordable electricity

Recent studies by Synapse highlight a solution to bringing down the cost of electricity for industrial customers that want to electrify: alternative rate structures. These alternative rate structures incentivize load flexibility, which electrification technologies like thermal batteries or heat pumps with storage can enable at industrial facilities.

Rate designs that incentivize load flexibility fall into three categories:

- Time-differentiated rates, which lower energy prices during off-peak hours

- Demand charge alternatives, which adjust electricity charges to be more expensive when the grid is strained and less expensive when it's not

- Special electrification tariffs, which offer targeted, often temporary, discounts or custom rates for new electrified load

- Together, these approaches can make electrified heating more affordable by aligning customer bills more closely with times when the electricity grid has abundant and less costly energy.

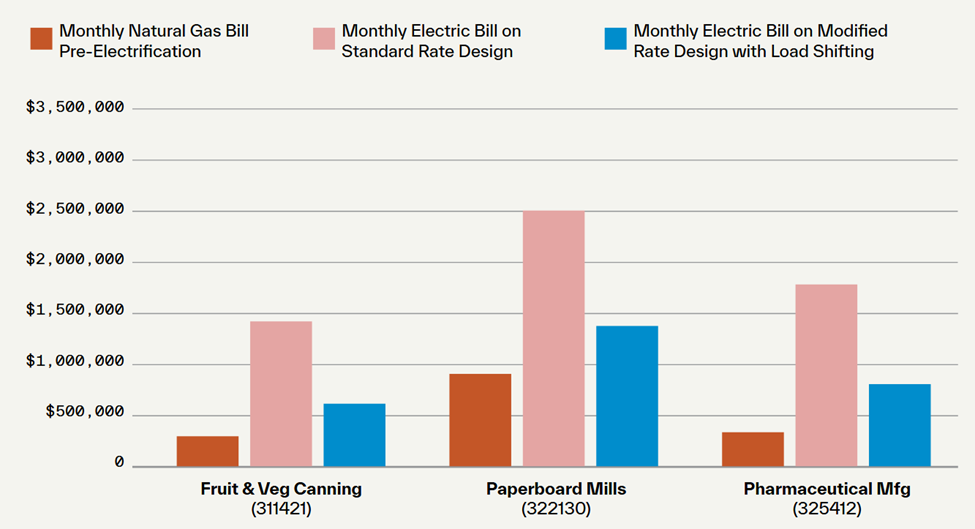

A December 2025 study by Synapse for the Sierra Club, Industrious Labs, and the American Council for an Energy-Efficient Economy modeled the energy savings, emissions abatement, and electricity bill impacts of electrifying industrial heating in California under alternative rate structures. We modeled the cost of electricity for industrial facilities that electrify with industrial heat pumps under standard industrial rate designs vs. a modified rate that recovers utilities' costs primarily based on use during peak periods. We found that with load-shifting, these alternative rates dramatically improve the economics of electrification for industrial customers. But while the alternative rates bring the economics of electrification closer to cost parity with gas heat, they still do not overcome the fundamental spark gap challenge (see Figure 2).

Figure 2. Monthly energy bills for analyzed industrial subsectors pre- and post-electrification, PG&E

Lower energy costs but lifetime costs remain high

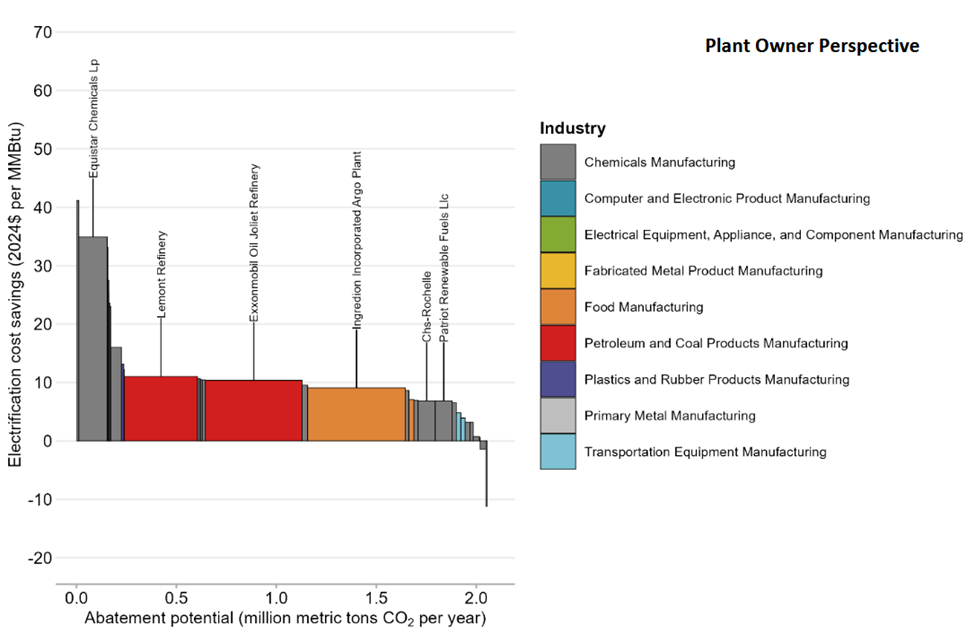

In a study for the Center for Applied Environmental Law and Policy, Synapse evaluated how alternative rates for utilities in Colorado and Illinois could reduce not only post-electrification electricity bills, but also overall lifetime costs for heating at the analyzed facilities. We estimated the total lifetime heating costs at industrial facilities by taking into account capital costs, operating costs, energy costs (fuel or electricity), and, for electrified equipment, potential cost of utility service upgrades. We found that alternative rate structures can dramatically reduce electricity bills for facilities that adopt thermal batteries or heat pumps with load-shifting capability. In fact, several facilities in each state showed more favorable all-in heating costs for thermal batteries than conventional heating technologies (see Figure 3).

Overall however, even with alternative rate structures and lower energy costs, we found that high capital costs for heat pumps lead to higher overall heating costs than conventional heating technologies.

Figure 3. Facility abatement potential and difference in levelized cost of heating for thermal batteries versus conventional heating technologies under an alternative rate structure, ComEd Illinois.

Load flexibility as a key electrification benefit

Synapse’s work on industrial electricity affordability underscores the importance of pairing electrification with load flexibility . Thermal batteries are inherently flexible, with their ability to charge when electricity prices are low and discharge heat on demand. Heat pumps have various options for flexibility: retaining backup heating; pairing with thermal batteries, steam, or hot water tanks for storage capability ; variable-speed and dynamic controls; and operational strategies such as rescheduling or batching energy-intensive processes to reduce demand during peak-price hours.

Ultimately, industrial electrification will only scale if electricity is affordable enough to compete with fossil fuels. Our research shows that rate design is one of the most powerful tools regulators and utilities have to close the spark gap—a necessary to move industrial electrification from pilot projects to a viable, competitive pathway for U.S. manufacturing in a low-carbon economy.